The primer dried off really quickly and I decided to hit it with the top coat the next day as the weather remained pretty good.

Again I have used Jawel Paints, this time I went for a 1K Synthetic Enamel paint as it’s much harder than other types of paint, ideal for tools and hard wearing equipment. The only downside is that it takes forever to dry and can take 2-3 weeks to cure fully.

The colour I chose in the end was RAL5019. It;s not an exact match as it is a much more vivid blue than the original, but I bought this paint off of the internet after doing some searching, the RAL colour was mentioned as being similar.

I did not want to have to resort to having to obtain RAL colour chips and matching it up exactly so I went for one that is close enough.

Having cut up a few metal coathangers to hang the parts from, I set about mixing up some paint and getting it into my gravity spray gun.

Here’s the result. Initially the paint went on nice and smooth, but I adjusted the gun a little bit and did not notice whilst spraying that the gland nut around the trigger had worked loose, this seemed to affect the finish and impart a bit of texture, however I am actually quite happy with it, after all it’s a work bench.

As you can see from the image below, the new paint is not an exact match for the complete workmate next to the newly sprayed one, but I think it’s not too bad and still holds a similar tone. I see it as a modern take on a classic.

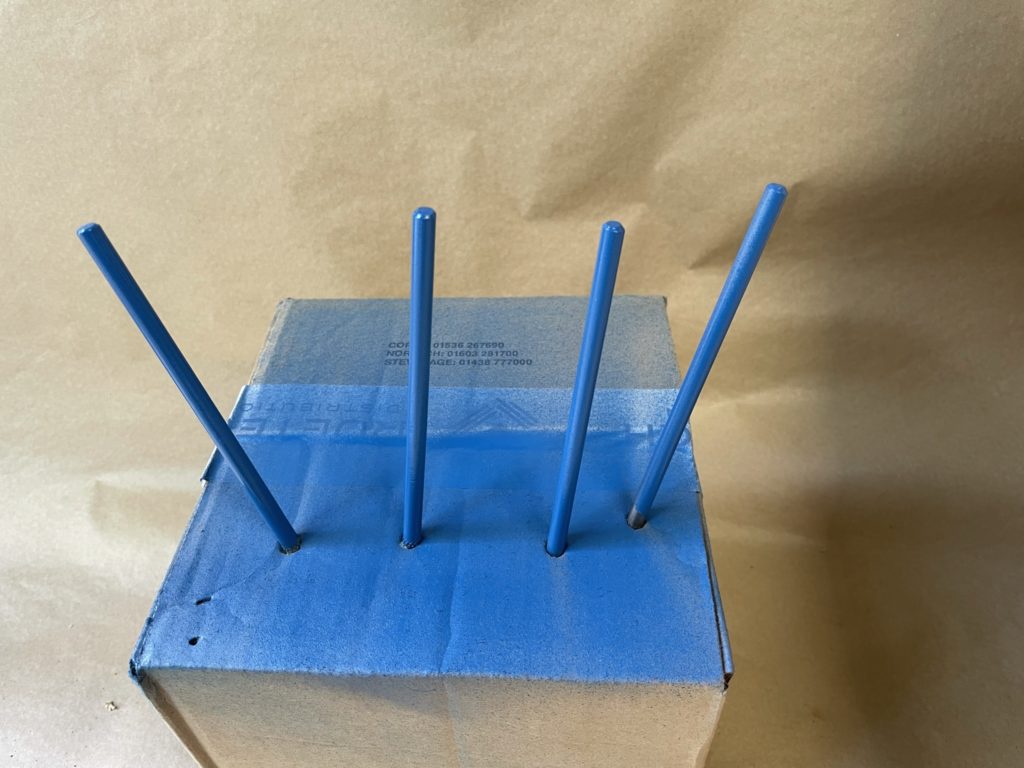

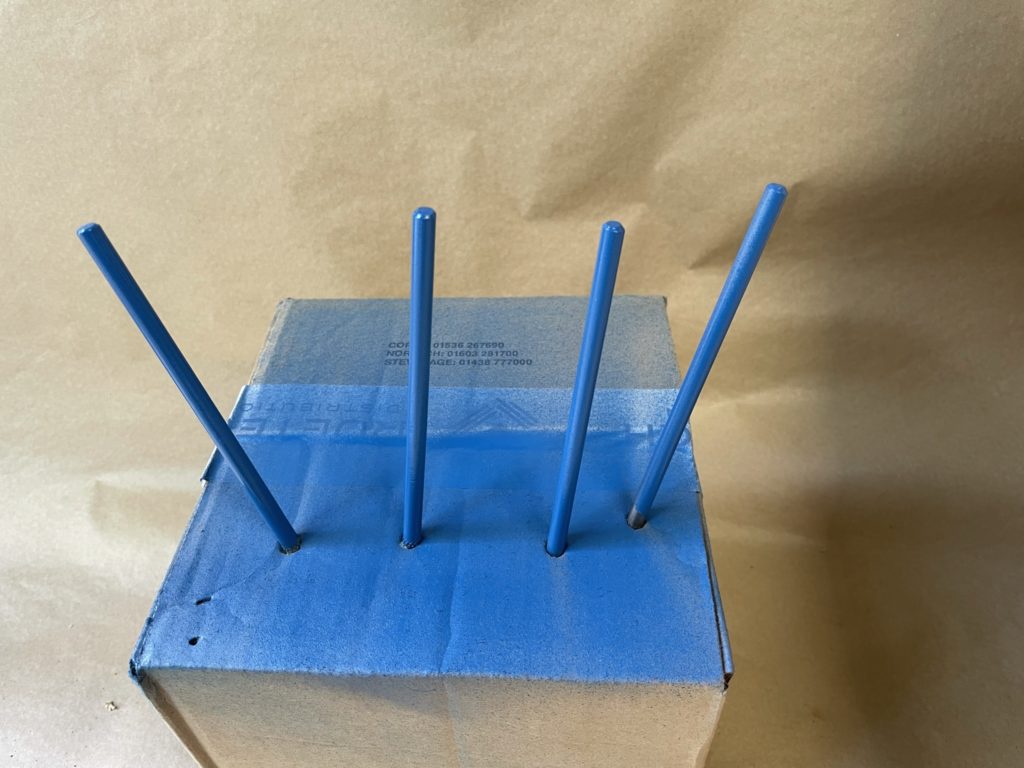

The four legs in all their freshly painted glory.

The side rails that hold the H frames and the jaws.

These are the leg hinge pins all painted up.

Now all I need to do is wait a couple of weeks for the paint to harden and I can start reassembly.